|

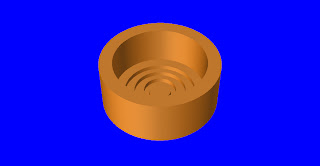

| This is an awesome... uh... thing? |

|

| It's a hookah! |

Hookah used to be one of my favorite vices. But nowadays not so much. Tobacco is bad for you no matter how you smoke it - simply filtering the smoke through the water in the bottom of the hookah doesn't reduce any of the carcinogens to any level that could be considered 'safe'. Plus I started to just not enjoy it. I tried as hard as I could to get a great hookah going. I ditched self-lighting coals - the chemicals on them tasted horrible. I used natural, less-processed coals despite the fact you need to light them on a range burner. They tasted better and produced better, fuller smoke. The only problem is that they get so hot that they burn the shisha under them badly and quickly. Or the air flow would be so bad they don't really start burning well at all and none of the shisha gets burned at all. That's wasteful. A good, well lit and packed hookah can be enjoyed for maybe an hour. My typical experience these days is either everything burns up in 15 minutes and produces acrid, thin and disgusting smoke, or everything remains unburned and no smoke is produced at all.

I don't enjoy that at all. The hot coals are theoretically good, but they require adequate air flow and some method to moderate the heat they produce.. That thin layer of tin foil separating the shisha from the coal typically has many small holes that produce good air flow (if the coals aren't blocking them completely) but don't moderate the heat at all. There are metal plates that can be used instead of or with the foil to provide a somewhat larger measure of heat moderation. The problem with them is that they are thin and have large air holes in them. Thin means they provide a low level of heat moderation and large air holes means that air flow isn't directed around the coals to keep them lit.

In short, none of the available solutions is very effective.

As an engineer I feel I can't let this situation stand. How difficult can it be to create some sort of metal grate that will distribute the heat of a burning coal while still providing good air flow - and additionally providing some means to ensure the coals don't slide off the bowl and leave burn marks in your carpet - such as this:

Well hard is it to design something like this? I'm an electrical engineer, so I don't really know anything about, well, I'll make a list:

- Materials - What kind of metal will have good thermal conductivity and has high machinability characteristics but not produce, say, any poisonous gases when exposed to the heat of a lit coal? Where do I even buy all this material? Aren't there a lot of different options?

- Machining - How is such a thing as this made? I've seen a CNC mill, but I don't own one, know how to use one, or even know what sort of information I need to give someone to be able to make something using one. What sort of tolerances can I expect? Can I design something with .01" dimensions and expect that it will come out right?

- Cost - How much will this be? How do I make it less expensive?

I have three different hookah bowl types. I want this thing to sit nicely and securely inside the bowl and not move around. So, first step, measure the inside diameters of each of the bowls so I can figure out what sort of lip I need to design into them. For measurements like that you need every engineer's best friend:

If you don't own one of these, buy one. I'll help, clicking on this link makes me happy: 6 Inch LCD Digital Caliper with Extra Battery and Case My favorite part about that one: the supplier is 'Generic'. I love China. You can measure anything with these very accurately. Saves your life when doing anything mechanical. They're great for PCB work - particularly for drawing your own footprints.

So this starts me off with at least some idea of what I need to make. Let's start drawing something. I could go old school and start off with pencil and paper but this is the 21st century. We have computers with CAD software - but which to use? I've never had to do any mechanical design like this before.

Lucky for me I've been at this a while. I can't even remember where I heard of it first, but I knew that eMachineShop.com existed. It's something like PCB123 or ExpressPCB but for mechanical parts. They provide you with free CAD software that is capable of:

- Drawing out what you want to make

- Generating a 3D rendering of your design (very useful)

- Deciding what machines/processes would be suit your widget

- Presenting you with a list of materials with information on machinability, typical uses, cost and other information as well as making limited recommendations about which materials to use for your design.

- Calculating the cost and delivery time for your part right from the program.

- Placing an order for your part.

I eventually decided on a design that looks a lot like the picture above. It will be made from 316 stainless steel (the same type as is used in pots and pans - that should be pretty safe) and fit three different bowl types. On the inside there are ridges that the coals sit on top of. In the troughs of the ridges the holes will be drilled. These holes in the troughs allow air to flow freely over the coals - the holes will never be completely covered by the coals because the coals can't fit into the trough. This fixes the airflow problem. The bottom plate is about a quarter inch thick still - this will spread the heat out and not just burn the top layer of shisha to cinders. And the walls are an inch and a half high to prevent coals from falling off (and helps to block drafts). Overall I'm rather pleased. I think I could use about 3-5 of these as a prototype - I'll hand some out to my hookah-smoking friends and get some feedback. So how much will it cost?

Oh, only $500 for three of them? Well, at prices like that I might as well get a dozen eh? Now don't get me wrong - I think this idea actually has product potential. I'm up for investing in a prototype if there's a payoff, but no matter how many units I pretend to buy (I went all the way to 10,000 units) the cost/unit is still around $30. I'd have to sell it for around $50 and for that cost I wouldn't buy it. Something has got to give. Perhaps I can talk to local machine shops and see if I can get cheaper machining?

This isn't a bad idea - there are plenty of local machine shops. I hate calling people, so I use email. I narrowed the list down to about five that I actually liked. What was my criteria? Basically, how amateur their web page looked. No, I'm not joking. Places that talk about machining parts for the space shuttle? No thank you. Places that talk about making awesome chrome instrument panels for your motorcycle? Yes please. Places that discuss ISO 9e8 quality processes and micron-level attention to detail? Sounds expensive. Places that have pictures of bearded men wearing leather gloves inhaling metal shavings? Now you're talking my language. Places that say they'll work with you and specialize in prototype production runs? Yes! Look, I'm an amateur, but I'm not unprofessional and I'm not looking for a disreputable machine shop. I'm looking for the one that will understand my plight the most - forgive my crazy unrealistic demands, help me decide what materials are safest, hold my hand through the difficult and unknown process of machining metal. I'm in unknown territory and I'm looking for the people that will have the most patience and tolerance of a difficult designer meandering his way through a low-profit job. I'm looking for someone humble and helpful.

Luckily, the eMachineShop software can produce DXFs, and from what I understand about mechanical design, that's a thing. So I proudly send off my DXF, acting all professional with my talk of what materials and processes to use (entirely cribbed from the eMachineShop software mind you). And they get back to me very quickly!

'Uh, we don't really use DXFs, can you give us a PDF drawing or something?'

'Do you have an STL file? Or maybe a PDF with measurements?'

'Can you maybe draw it out... and send us a PDF?'

What?! Don't these people realize that we're in the 21st century?! That's practically the future! Fine - you know what? My dad taught me how to draw things out, I have graph paper, I've seen mechanical drawings and I know how to measure. So bring it on!

I printed out a cross-section from the eMachineShop software, sat down with my ruler and mechanical pencil and started marking out measurements. And boy, was it a mess. My design was absurdly over complicated. I had angles other than 90 degrees all over the place (but they looked pretty!). I had about fifty different measurements to mark when only about 4 of them actually mattered. I just plain didn't align anything to anything else - wherever I had the choice to line up two lines I just didn't. It didn't matter - the software made it seem like all design decisions were equal and it's all getting built by machines anyhow. If the Design Rule Check doesn't complain, who cares?

But now I was dealing with people. People who would have to do more work to handle my absurd design. People I would actually have to talk to. Most importantly - people I asked for help. Who might criticize my design. I wanted to try extra hard to do the best I could - you know, to avoid embarrassment. There will probably be plenty of that anyway given how little I know about mechanical design.

So I go back to the drawing board. I have my important dimensions, so I start with those, but then I start aligning everything together to make it a more organized, simpler mess than before. I also do a bit more research into materials and find some interesting information. Did you know that aluminum is less expensive than stainless steel? Heck, most things are less expensive than stainless steel. More importantly, anodized aluminum is used in cookware - high heat tolerant and still people-safe! And wouldn't you know it - eMachineShop offers anodizing services and there are several local shops that will too. Now, with the less-complex design and different materials even the eMachineShop price per unit at 100 units is about $13. This is much more lucrative to sell. Plus, anodizing aluminum means you can color the metal. Everyone loves color and everyone loves choosing colors - very customer-worthy. Aluminum also cuts down on weight, which cuts down on shipping. It's a win-win-win situation. Here's the revised, simplified design:

|

| Look at that lovely handwriting! |

So, for any electrical engineers wanting to try their hand at mechanical design, here's some bullet points to get you started:

- Get a good set of digital calipers

- Sketch everything out on paper to start with (use pencil, not pen)

- Minimize the complexity of your part by minimizing the number of measurements it takes to describe it

- Use the eMachineShop software for help with manufacturing processes and materials and a quick price-check

- Use Google to look for local machine shops - they've been nothing but helpful to me so far and potentially less-expensive than online shops

No comments:

Post a Comment